QQ:845707390

Contact:Mr.lin

Tel:0086-576-86333711

Fax:0086-576-85046659

E-mail:677@63177.com

Whatsapp: +86 13906863881

Add:NO.1,Hou’an Villiage, Daxi Town,Wenling City, Zhejiang ,China

- Name:

- Laser Marking Machine with I/O for PLC

- Comments:

- Special laser marking machine with I/O for PLC control.

The extended I/O support signals like "start marking", "stop marking", "busy", "finished marking", "file select".

- View:

- 4538

- Contact:

- Contact Us

Summary

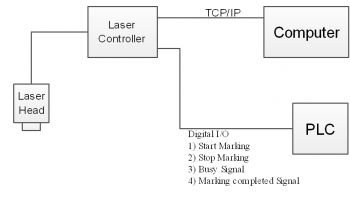

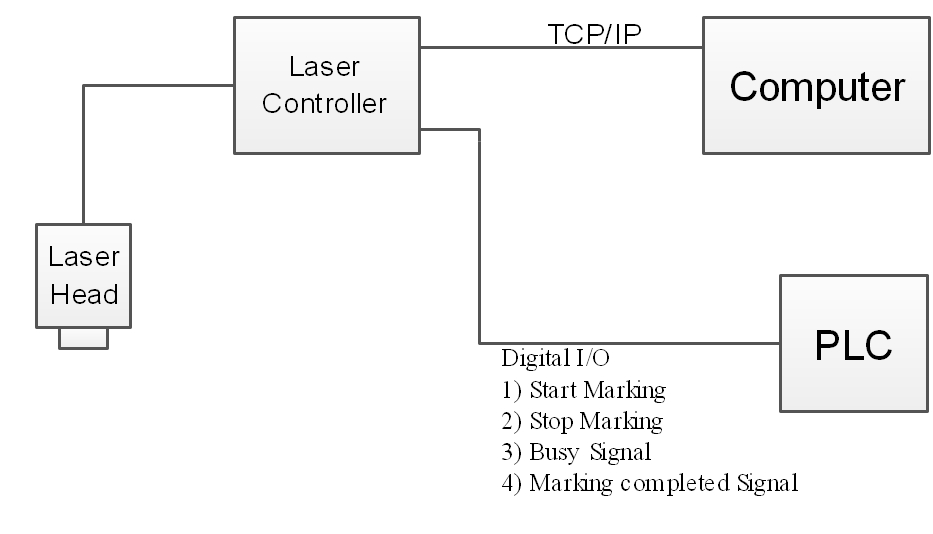

For automatic laser marking, NCSK designed customized laser marking machine which can connect with PLC。Custom function including:

1)Extended I/O for PLC communication

2)Communication protocol

3)Software Development Kit(SDK)

Figure 1-1 Automatic laser marking solution

2. Extend I/O for PLC communication

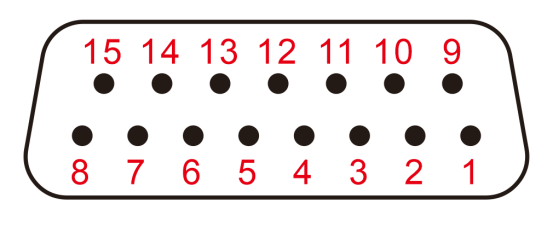

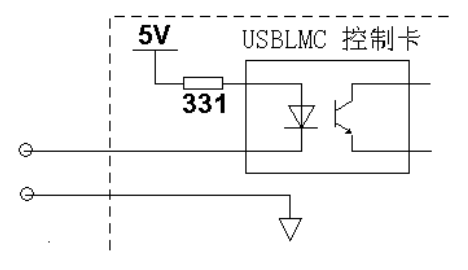

PLC need control signal and state signal to control the laser marking machine. So we add these signals in an extended I/O. The extended I/O can be DB15 or DB25, depending on how many signals need to be used.

Figure 2-1 Laser Marking Machine Extended I/O for PLC control

2.1 General Input Signal

General Input Signals are use for controlling the working state of laser machine。Including:

1)Start Marking Signal:Machine start making when it’s active.

2)Stop Marking Signal:Machine stop marking when it’s active, and show warning information.

3)Safety Door Signal:Machine stop marking when it’s active.

4)File Select Signal:Use input signal to select the right file to marking。For example,INPUT[6:4] ”001” select file A to marking,INPUT[6:4] “010” select file B to marking。

Extended I/O support 8 general input signals,figure 2-2 shows the pin diagram:

Figure 2-2 Pin diagram of input signal

2.2 General Output Signal

General output signals show the working state of laser marking machine。

1)Busy Marking:Active when machine is marking

2)Finished Marking:Output an pulse signal when finished marking.

3)Red light indication signal:Active when Red light is indicating。

The output signal is TTL output by default. Short circuit or grounding should be avoided.

3. Communication protocol

In normal laser marking system, you can modify the content of mark by serial port or ethernet port. But you can only modify one content before marking.

So we design a communication protocol.

With this protocol, you can modify any mark any content before laser marking.

Example:

| Instruction code | Mark address | Data | CRC code |

| TR | 01 | NCSK001 | ABF0 |

Intruction code: Code of instruction

Mark address: Define which mark you need to modify

Data: The new content of the mark

CRC code: CRC check code

The procotol also define the feedback massage formate, and other instruction, for detail document, please contact us.

4. Software Development Kit (SDK)

NCSK also supply SDK for secondary development of software. With this SDK, you can integrate the core functions of laser marking software into your own program.

The SDK is suitable for Windows system environment and the development language is C++. Figure 4-1shows a demo program developed by this SDK.

Figure 4-1 demo program developed by SDK

Online message

Online message Collect

Collect Map

Map 中文版

中文版 English

English